'Thermal mass' describes a material's capacity to absorb, store and release heat. For example water and concrete have a high capacity to store heat and are referred to as 'high thermal mass' materials. Insulation foam, by contrast, has very little heat storage capacity and is referred to as having 'low thermal mass'.

A common analogy is thermal mass as a kind of thermal battery. When heat is applied (to a limit) by radiation or warmer adjoining air, the battery charges up until which time it becomes fully charged. It discharges when heat starts to flow out as the adjoining air space becomes relatively cooler.

Though thermal mass has always been an aspect of buildings, only in recent years has it evolved as a tool to be deployed in the conservation of energy. The report 'UK Housing and Climate Change' by Arups in 2005 in particular was seized upon by manufacturers of high thermal mass materials as the raison-d'etre for 'heavyweight' construction. Arups painted a picture of increasing temperatures across the UK and argued that future Mediterranean climatic conditions justified the employment of heavyweight construction. Arups were right - to an extent (though both masonry and timber frame construction types can accommodate thermal mass), but the immediate hijacking of the report by manufacturing sector interest and its subsequent pervasiveness has continued to hide the more complicated message about thermal mass: that it is not a 'one size fits all' concept.

Understanding the properties of thermal mass and its use, particularly in context, is critical to realising both benefits and potential pitfalls.

Thermal admittance, or 'Y-value,' or Heat transfer coefficient

Thermal admittance quantifies a material's ability to absorb and release heat from a space as the indoor temperature changes through a period of time. Admittance values can be a useful tool in the early stages of design when assessing heat flows into and out of thermal storage.

Admittance is measured in W/(m2K). So that

h = ΔQ / A x ΔT

Where: h = heat transfer coefficient, W/(m2K)

ΔQ = heat input or heat lost, W

A = heat transfer surface, m2

ΔT = difference in temperature between the solid surface and the adjacent air space.

Higher admittance values indicate higher thermal mass.

Thermal admittance is fully described in EN ISO 13786:2007. The framework described also provides the basis for the CIBSE 'Simple Dynamic Model' for calculating cooling loads and summertime space temperatures (CIBSE (2005) Guide A: Environmental design).

Admittance values for typical external wall elements (based on a 24 hr cycle)

| External wall | Internal finish | Admittance value |

| Timber frame (brick outer leaf) | Plasterboard | 1.0 |

| Wet plaster | ||

| Masonry cavity wall (100mm aircrete block) | Plasterboard | 1.85 |

| Wet plaster | 2.65 | |

| Masonry cavity wall (100mm dense aggregate block) | Plasterboard | 2.65 |

| Wet plaster | 5.04 |

Source: The Concrete Centre (calculated according to EN ISO 13786:2007)

Factors that determine thermal mass

|

Specific heat capacity |

| Specific heat capacity refers to a material's capacity to store heat for every kilogram of mass. A material of 'high' thermal mass has a high specific heat capacity. Specific heat capacity is measured in J/kg.K | |

|

Density |

| The density refers to the mass (or 'weight') per unit volume of a material and is measured in kg/m3. A high density material maximises the overall weight and is an aspect of 'high' thermal mass. | |

|

Thermal conductivity |

| Thermal conductivity measures the ease with which heat can travel through a material. For 'high' thermal mass, thermal conductivity usually needs to be moderate so that the absorption and release of heat synchronises with the building's heating and cooling cycle. Thermal conducitivity is measured in units of W/m.K |

The effectiveness of some common materials:

| Material | Specific heat capacity | Thermal conductivity | Density | Effectiveness | |

|

water | 4200 | 0.60 | 1000 | high |

|

stone | 1000 | 1.8 | 2300 | high |

|

brick | 800 | 0.73 | 1700 | high |

.jpg) |

concrete | 1000 | 1.13 | 2000 | high |

|

unfired clay bricks | 1000 | 0.21 | 700 | high |

|

dense concrete block | 1000 | 1.63 | 2300 | high |

|

gypsum plaster | 1000 | 0.5 | 1300 | high |

|

aircrete block | 1000 | 0.15 | 600 | medium |

|

steel | 480 | 45 | 7800 | low |

|

timber | 1200 | 0.14 | 650 | low |

|

mineral fibre insulation | 1000 | 0.035 | 25 | low |

|

carpet | - | 0.05 | - | low |

SAP and thermal mass

SAP 2009 uses thermal mass in calculating the heating and cooling load of the building.

SAP uses the kappa (k) value to determine thermal mass. 'k' is the measure of the heat capacity per unit area in kJ/m2K of the 'thermally active' part of the construction element:

k = 10-6 Σi pi ci di

pi = the density of the layer 'i' in the construction (kg/m3)

ci = the specific heat capacity of the layer 'i' (J/kg K)

di = the thickness of the layer 'i' (mm)

The calculation is done over all the layers of the construction element, starting at the inside surface and stopping at whichever of these conditions occurs first (including its occurrence part-way through a layer):

• half way through the construction

• an insulating layer

• a maximum thickness of 100mm

It is used in the calculation of the Thermal Mass Parameter (TMP):

TMP = Cm / TFA

Cm = sum of (area x heat capacity) construction elements

TFA = total floor area

The 'k' value is a relatively crude way of determining thermal mass. It makes assumptions about the extent of the thermally active volumes of a material and ignores the effect of thermal conductivity in calculating the period over which heat is absorbed and emitted from the material.

ISO 13786 provides a more effective method of determining thermal mass.

How thermal mass works

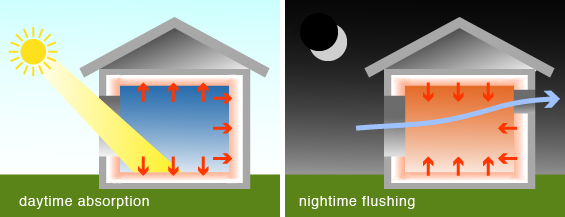

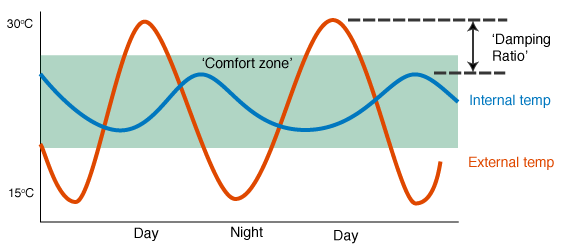

By alternately storing and releasing heat, high thermal mass 'smooths out' the extremes in daytime temperatures. In warm /hot climates where there is significant temperature variation between day and night ('diurnal' variation), heat is absorbed during the day and then released in the evening when the excess can be either 'flushed out' through natural ventilation or it can be used to heat the space as the outside temperature drops. The entire process can then be repeated the next day.

Summer cooling

Winter heating

The pattern of heating and cooling need not be that of diurnal temperature variations. For example where patterns of human activities such as in offices or schools exist, thermal mass can be designed to absorb heat generated by office machinery, lights and humans themselves and then released when occupation of the space ceases.

Locating thermal mass

• Thermal mass should be exposed ('coupled') to the heated internal space.

• Thermal mass needs to be isolated from the influence of external air temperatures. This is achieved through locating the mass within the insulated building envelope.

• Any heavyweight material will serve as thermal mass. It can form any part of the internal fabric, be it floor, walls or ceiling.

• Though often desirable, thermal mass does not need to be exposed to direct sunlight for heat to be absorbed. Heat can be conveyed through convection and radiation between other surfaces.

Effective thickness

Considering thermal mass on a daily cycle basis, the most effective depth of the material is the first 50 mm. Between 50 and 100 mm, efficiency further diminishes and beyond 100 mm the mass effect is largely inconsequential.

The importance of thickness and thermal mass is a key in developing opportunities for including significant thermal mass in lightweight construction. A number of systems have been recently developed that demonstrate that although external walls can be of super-insulated timber frame type, internal finishes including floors, ceilings and partition walls can provide sufficiently high thermal mass without resort to masonry construction (eg RuralZed)

Exposed terracotta ceiling blocks providing thermal mass to timber frame construction

Thermal mass and housing in the UK

In all instances of designing with thermal mass, use of computer simulation is clearly essential.

In addition to the Arups report, a number of simulation-based studies have been undertaken to look at the interplay of insulation, ventilation, occupancy and latitude.

• In future scenarios that reflect a warming climate, housing in the south of England receives significant benefit through using thermal mass combined with shading to mitigate the effect of summer time peak temperatures. At higher latitudes the benefit becomes relatively less. 1

• Lower thermal mass construction in the south of the UK can be marginal even when shuttered at times of peak summer temperatures. 1

• At higher latitudes there is little need for thermal mass to moderate low summer temperatures. Where thermal mass is included consideration should be paid to the supplementary heat required to heat the mass before the air temperature rises. The Tuohy et al study showed that at higher latitudes, the use of thermal mass could be counter productive.

Passivhaus and thermal mass

The distinct concept of Passivhaus is that of the super-insulated box ventilated by mechanical means. So efficient is the combination of insulation and air-tightness that the building requires little more than the heat from humans and domestic operations to keep the overall internal temperature at comfortable levels that vary little without extraordinary input - whether it be solar gain, or the extra heat generated by people and machines.

Because thermal mass distinguishes itself as a tool for dampening of temperature amplitudes, it works best where excessive heat builds up and requires absorption and much later disposal. For example, where the excessive heat generated by solar-gain is absorbed by the building fabric during daylight hours or where in a school environment excess heat is generated by students and absorbed for emission into a cooler night-time space.

Where buildings normally experience these kind of temperature differences, the use of thermal mass can make plenty of sense - but where there is little normal amplitude variation typical of a Passivhaus dwelling, the case for the special consideration and use of thermal mass starts to become more marginal and complicated.

In houses, as the climate becomes warmer, the more noticeable heat load will increasingly come from solar gain during summer months. In a Passivhaus dwelling the gain will present a significant challenge to the design of the house. Arguably one way of dealing with the heat will be to use thermal mass to absorb the excess - but to avoid overheating, it will be usually necessary to flush away the heat during the night. A good deal of opening of windows will likely be needed - and then will be only successful if the night-time temperature is sufficiently below that of the day-time peak.

Another alternative would of course be to prevent solar gain through control of how much sun is transmitted into the building. Either way, the design and use of thermal mass will be carefully integrated into the context of both other controls and the pattern of use of the particular building. Thermal mass will be dependent on context.

Developing technologies and techniques

.jpg)

• Phase change materials that provide heat capacity by changing phase. Particular effort is being directed at materials based on the change of paraffin from solid to liquid phases. Products include aluminium clad panels containing paraffin (see Dupont Energain above( and encapsulated paraffin capsules mixed with plaster.

• Use of solid wood panel construction - provide helpful degrees of thermal mass whilst limiting the amount of embodied energy found in masonry construction.

• Continuing design research examining the optimisation of thermal mass materials within timber frame buildings.

References

1 Thermal mass, insulation and ventilation in sustainable housing - an investigation across climate and occupancy - Tuohy et al 2004

Read more about Building Physics:

- Heat transfer: Conduction, Convection & Radiation MORE

- Insulation materials: thermal properties MORE

- U-value for dummies MORE

- Air tightness MORE

- Air barrier design MORE

- Thermal bypass MORE

- Decrement Delay & Thermal buffering MORE

- Thermal mass MORE

Disclaimer:

GreenSpec accepts no responsibility or liability for any damages or costs of any type arising out of or in any way connected with your use of this web site. Data and information is provided for information purposes only, and is not intended for trading purposes. Neither GreenSpec nor any of its partners shall be liable for any errors in the content, or for any actions taken in reliance thereon.