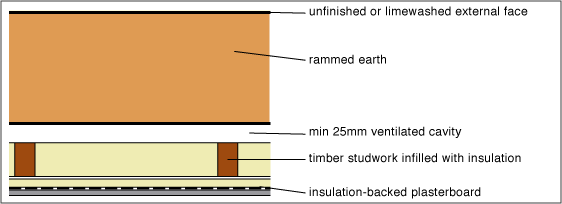

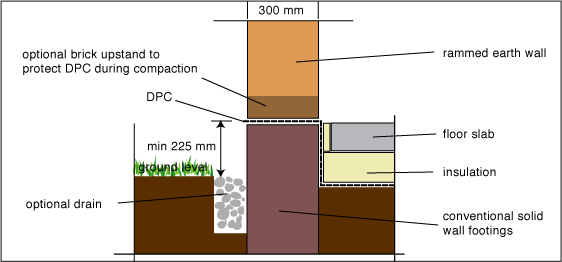

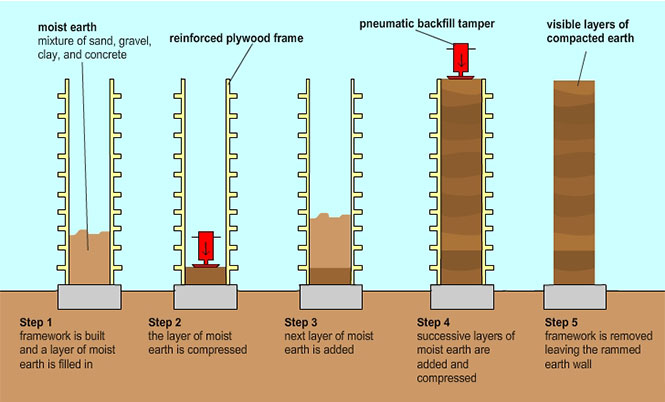

• Rammed earth walls (aka pise) are constructed by the compacting (ramming) of moistened subsoil into place between temporary formwork panels. When dried, the result is a dense, hard monolithic wall.

• A vernacular green building material as well as in more recent 'Eco houses', rammed earth is an ancient form of construction, usually associated with arid areas. There remain plentiful examples of the form around the world – evidence that rammed earth is a successful and durable way of building. A few historical rammed earth buildings are to be found in the UK.

• In recent years, rammed earth has become popular amongst environmentally-conscious architects as well as those seeking an element of exoticism. Contemporary examples include:

- The AtEIC building at CAT in Powys

- The Genesis Project in Somerset

- Rivergreen Centre at Aykley Heads in Durham

- Pines Calyx conference centre

- The WISE conference centre at CAT

• Though there is a growing number of buildings including rammed earth in the UK, its prospects of entering mainstream construction as a structural material are limited due to formwork and labour costs involved together with a climate that has relatively high humidity and moderate external temperatures.

• The likely future for the application of rammed earth is as:

- Thermal mass.

- Internal load-bearing unstabilised walls.

- External load-bearing stabilised walls.