Installing or upgrading loft insulation is probably the quickest and most efficient method of improving the thermal performance of an existing building. But though adding insulation is straightforward enough, an understanding of the moisture and ventilation dynamics within the roof space is important to avoid the risk of condensation.

Ventilation: prevention of condensation

• One of the major threats to the integrity of a timber structure is through the build-up of condensation

• Condensation occurs where warm moist air comes into contact with a cold surface. Within building fabric, without the prevention of condensation, the presence of damp is likely to lead to the decay of vulnerable, particularly timber, components.

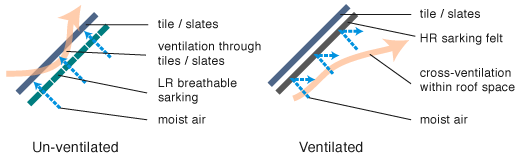

• The way moist air is handled within a roof helps define the type of construction.

• BS 5250: 2002 provides guidance to the control of condensation in pitched roofs

Ventilated roof space (traditional loft construction)

• The traditional ‘cold roof’ or ‘loft’, found in the vast majority of existing buildings, handles moist air from inside the building by allowing it to diffuse through the ceiling into the roof void from where it is removed through cross ventilation.

• A ventilation path of at least 25mm in width is required between the insulation and the u/s of the sarking.

• Holes and gaps in the ceiling should be sealed to restrict the amount of moist air entering the roof space (see also ‘air tightness’)

• For roofs over 35o pitch, or over 10m span, ridge ventilation is required equivalent to a continuous 5mm gap.