Insulation and concrete slabs

Solid ground floor insulation in context

The temperature difference between an internal space to ground is significantly smaller than the temperature difference between the internal space to outside air. In general, recent research (George, Geens & Graham, BFF, Spring 2006) has shown that solid ground floor insulation as an addition to well-insulated walls and roof, contributes very little to the building’s overall thermal performance. The designer should balance the extra benefit(s) attached to installing a new slab with the cost, marginal carbon gains and pragmatics involved.

Space heating reaction time

When considering the location of the insulation below or above the slab, it is useful to consider the likely heating use pattern of the occupiers.

- Where a quick heating response time is required, for example when a family returns home in an evening, insulation above the slab should be considered.

- Where heating is used over more prolonged periods, for example where a space is occupied throughout the day, the thermal mass provided by a slab over the insulation should be considered.

Compression resistance

When assessing the suitability of an insulation material, it is important to ensure that the material has adequate compression resistance to restrict the effects of the compressive load applied by any loading:

Dead load

Dead load is the weight of the floor finish upon the insulation material. Refer to BS 6399: Part 1: 1996 for more guidance.

Design load

Design load is the load applied in use. These loads are usually localised or point loads associated with the use of the floor (eg furniture) and result in increased localised loading acting on the insulation. Likely point loading should be considered in calculating the required thickness of floor finish, particularly where the insulation is located above the slab.

NB

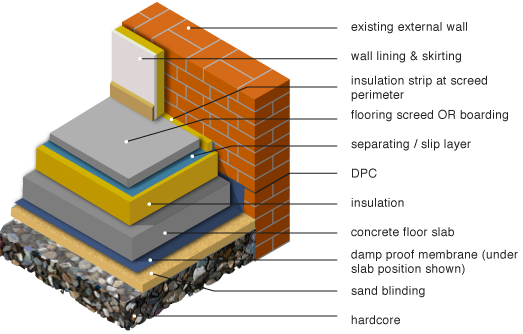

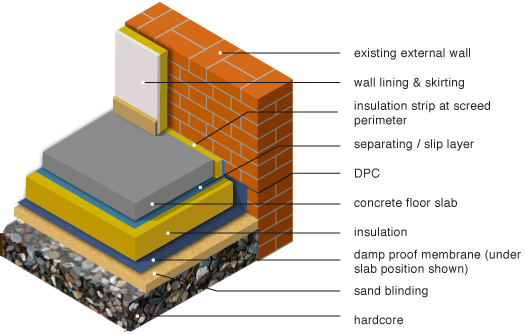

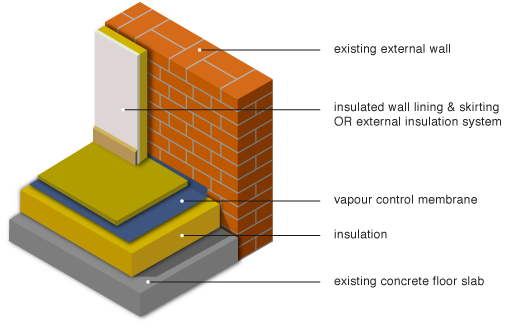

The ground floor insulation examples illustrated below are for general guidance only. The performance of products and methods of fixing vary. When specifying, confirm with the product manufacturer their installation methods and expected performance.

Ground floor insulation methods

1 Upgrading an existing slab

• The simplest way of improving the thermal performance of an existing concrete ground floor is to add insulation and a new floor deck on top of the existing floor.

• Though simple, raising the floor level through added insulation will usually require skirtings and radiators to be removed and re-fixed and doors to be reduced in height. Other problems might include unequal step heights at staircases and the raising of step heights at external doors. It might be considered that these problems are irreconcilable with building regulation requirements and could rule out this method of insulation.

• Ensure that any remedial work is undertaken on the slab ahead of installing the insulation.