• Around 6% of the total national delivered energy use in the UK is accounted for by domestic water heating.

• An average late-20th century 3 bedroom semi is responsible for emitting around 4200 kg of CO2 per year. Hot water is responsible for 864 kg of that total.

• Solar collectors are a well-tried and tested technology.

• They are suitable for both new-build and retrofit.

• A system will typically provide 40-50% of annual domestic hot water requirements.

Solar collector technology

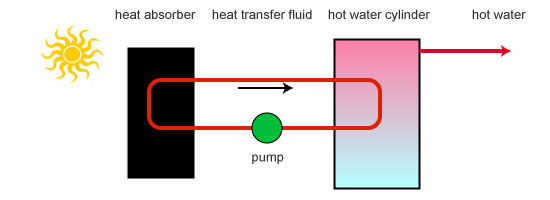

A solar water heating system has as its main component a collector. The function of the collector is to capture the sun’s energy falling on it in the form of heat to the fluid in the collector. The 'indirect' circulation system is the most common:

The main common component of solar collectors is the absorber plate. A coated metal plate absorbs the sun’s radiation and causes its temperature to rise above the ambient. The plate then releases energy through radiation and convection to its immediate surroundings. Heat is thus transferred to the heat-transfer fluid which in turn feeds the hot water system.

Types of collector: two general categories

Flat plate collectors

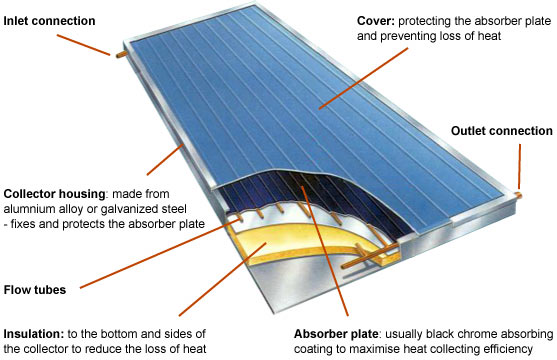

A flat-plate collector consists of an absorber, a transparent cover, a frame, and insulation. Usually an iron-poor solar safety glass is used as a transparent cover, as it transmits a great amount of the short-wave light spectrum.

Only very little of the heat emitted by the absorber escapes the cover (greenhouse effect).

In addition, the transparent cover prevents wind and breezes from carrying the collected heat away (convection). Together with the frame, the cover protects the absorber from adverse weather conditions. Typical frame materials include aluminium and galvanized steel; sometimes fibreglass-reinforced plastic is used.

The insulation on the back of the absorber and on the side-walls lessens the heat loss through conduction. Insulation is usually of polyurethane foam or mineral wool.

Evacuated-tube collectors

In this type of vacuum collector, the absorber strip is located in an evacuated and pressure proof glass tube. The heat transfer fluid flows through the absorber directly in a U-tube or in counter-current in a tube-in-tube system. Several single tubes, serially interconnected, or tubes connected to each other via manifold, make up the solar collector. A heat pipe collector incorporates a special fluid which begins to vaporize even at low temperatures. The steam rises in the individual heat pipes and warms up the carrier fluid in the main pipe by means of a heat exchanger. The condensed liquid then flows back into the base of the heat pipe.

The pipes must be angled at a specific degree above horizontal so that the process of vaporizing and condensing functions. There are two types of collector connection to the solar circulation system. Either the heat exchanger extends directly into the manifold ("wet connection") or it is connected to the manifold by a heat-conducting material ("dry connection"). A "dry connection" allows to exchange individual tubes without emptying the entire system of its fluid. Evacuted tubes offer the advantage that they work efficiently with high absorber temperatures and with low radiation.

Flat plate v Evacuated tube

The debate over the relative performances of flat plate and evacuated tube collectors rumbles-on - without either side seemingly able to deliver the 'killer' argument.

In general though, it is probably safe to say that for a given absorber area, evacuated tubes are more likely to maintain their efficiency over a wide range of ambient termperatures and heating requirements. In constantly sunny climates flat plate collectors are more efficient whereas in more cloudy conditions their energy output drops off rapidly in comparison with evacuated tubes.

Heat distribution

Solar heating primary circuits transfer heat from the solar collectors to the pre-heat cylinder. They may be ‘Direct’ or, in the UK, the more usual ‘Indirect’.